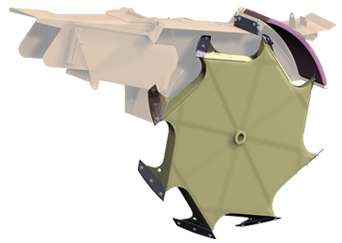

C-Kator

Straw Blower Chopper 3 – 6 m3

The C-Kator range of straw blowers chopper consists of two models of 3 or 6 m3. These machines have a unique cutting system that allows you to choose the length of the straw below 4 cm / 6 cm / 8 cm or above 10 cm.

See features

The advantages of using a chopper straw blower are many: better absorption, better and longer lasting litter, and a reduction in the number of bales used per year. This machine is suitable for strawbedding in poultry farming, strawbedding in cubicles and making premix for mixing machines. The machine is equipped with a right side chute for strawbedding up to 10 m deep. The machine's pick-up door guarantees independent loading of round bales up to 2 m in diameter and square bales 1.20 x 1.20 x 2.50.

- Mechanical shredder with V knives

- Hydraulic barrier

- Welded chopping rotor with 2 speed gearbox

- Manual chopping area

- Right lateral chute for strawblowing

- Self-loading rear door 600 Kg

- Electric control Comfort -C

- Articulated coupling

The addition of a sprayer offers convenience of use while it limits the appearance of dust, adjustable nozzles are located at the flow outlet to prevent clogging of the chute when straw-bedding. It is possible to add soluble additives to the tank to sanitise the straw and guarantee a clean straw bed for the animals.This system works simultaneously as the bed chain advances to avoid unnecessary use when the machinery is not straw-bedding.

The addition of a sprayer offers convenience of use while it limits the appearance of dust, adjustable nozzles are located at the flow outlet to prevent clogging of the chute when straw-bedding. It is possible to add soluble additives to the tank to sanitise the straw and guarantee a clean straw bed for the animals.This system works simultaneously as the bed chain advances to avoid unnecessary use when the machinery is not straw-bedding.

A cylinder above the cutting chamber opens or closes the chopping system from the electric control. This option allows the chopping size of the straw strands to be controlled from the cab to adapt the size of the strand to the application.

A cylinder above the cutting chamber opens or closes the chopping system from the electric control. This option allows the chopping size of the straw strands to be controlled from the cab to adapt the size of the strand to the application.

The mechanical shredder, fi tted with 6 discs and 48 V shaped knives, combined with a hydraulic comb which regulates the bale strike depth and the fl ow of material in the turbine. Welded turbine (Ø 1.6m 8 smooth blades) cuts and enables regular straw-bedding up to 10 meters.

The chopping system is based on the opening of the chopping chamber, which allows the straw strands to accumulate thanks to a recycling principle. The smooth knives cut the straw into short strands. When the chopping chamber is closed, the chopping system is deactivated and long chopped straw is produced for standard strawbedding.

Patented by Lucas G, this bevelled part is located at the outlet of the chute and ensures that the material exits without blockage. If a surplus of material is present at the level of the blade, the cut-off plate will remove it so that the following blade expels it. This system guarantees a sustained and homogeneous strawbedding even with glued straw. The cut-off plate promotes the suction effect for better strawbedding performance

- Poultry straw blowing 4cm: Chopping of the straw for better absorption. The litter is renewed better and remains in good condition longer.

- Cubicles straw blowing 6 cm: straw of intermediate size

- Crop straw blowing 6 cm: To protect crops from frost while retaining moisture.

- Mixing Premix 8 cm: to reduce mixing time in mixing machines

- spreading on straw bed 10 cm : long straw for standard straw blowing in cattle environment

Hydraulically driven, it has 9 moving speeds from 0 to 20 m/min.The speed is adjusted by the electrical control, the bed chain brings the material to the shredder. It can be moved forward or backward. Designed with 8 mm marine chains with bolt-on bars, it is guided and driven hydraulically by nuts for better centering and resistance to bale weights.

The rounded design enables self-loading and bale handling for round bales up to 2 m diameter and square bales up to 1.20 x 1.20 x 2.50 m. It has a door loading capacity of 650 kg. As an option, a second control station located at the door controls the opening and closing of the door and the moving floor.

Hydraulically swivelling 270° chute located in the extension of the turbine and the straw flow to guarantee a spreading distance of 9 m on the right side and 9 m on the left side. Hydraulically adjustable chute cover to modulate the spreading distance from the cab. This system allows precise spreading of strawspreading in buildings and stalls.