Castor 134-185

The Castor 13 and 18 m3 range of high volume straw blowers bale feeders are capable of processing all types of forage thanks to their 3 mechanically driven shredders. These straw blowers have been designed for the distribution of bulk products and have been optimised for the loading of round & square bales

See features

Lucas G has built its reputation on its range of CASTOR straw blowers which are renowned for their exceptional performance in all types of forage. These machines are capable of distributing and straw blowing all types of material, whatever the length of the strands and the percentage of moisture. The Castor 134 accepts up to 4 round bales of Ø 1.30 m and the Castor 185 up to 5 round bales. These machines are equipped as standard with a right lateral chute for a projection of 18 m, a dual speed gearbox and require a tractor power of 80 HP to be able to carry out the strawbedding and distribution operations.

Lucas G has built its reputation on its range of CASTOR straw blowers which are renowned for their exceptional performance in all types of forage. These machines are capable of distributing and straw blowing all types of material, whatever the length of the strands and the percentage of moisture. The Castor 134 accepts up to 4 round bales of Ø 1.30 m and the Castor 185 up to 5 round bales. These machines are equipped as standard with a right lateral chute for a projection of 18 m, a dual speed gearbox and require a tractor power of 80 HP to be able to carry out the strawbedding and distribution operations.

- Right lateral chute for feeding

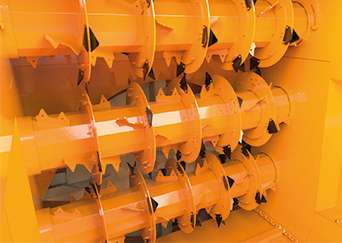

- 3 mechanical shredders Castor with V blades

- Two-speed single bloc welded Ø1800 mm turbine

- Fixed barrier

- Manual rear door

- Control of all functions in cab with 2 double acting distributors

The addition of a sprayer offers convenience of use while it limits the appearance of dust, adjustable nozzles are located at the flow outlet to prevent clogging of the chute when straw-bedding. It is possible to add soluble additives to the tank to sanitise the straw and guarantee a clean straw bed for the animals.This system works simultaneously as the bed chain advances to avoid unnecessary use when the machinery is not straw-bedding.

Designed to process all kind of fodder even difficult ones (wet silage) it is fitted with 5 or 7 smooth discs and 48 knives which guarantee a clean cut of products. The paddles located between the discs bring the cut material to the turbine and avoid long strands to wrap around the shredder.

This piece has been designed in a single block. Equipped with 6 blowing paddles, the material is launched up to 18 m with lateral chute and 15 m with the Universal chute. The turbine is integrated in a blowing conduit of 33 cm that avoid jamming problems and provide a steady workin.

Patented by Lucas G, this bevelled part is located at the outlet of the chute and ensures that the material exits without blockage. If a surplus of material is present at the level of the blade, the cut-off plate will remove it so that the following blade expels it. This system guarantees a sustained and homogeneous strawbedding even with glued straw. The cut-off plate promotes the suction effect for better strawbedding performance

The PTO drives the turbine directly via a two-speed gearbox. ( spreading speed / distribution speed) An angle transmission drives the shredder or shredders. The whole system is protected by a safety bolt to ensure the durability of the system. The electric clutch option allows a magnetic dissociation of the rotation of the fan and the shredders guaranteeing the interruption of the straw flow by simple disengagement.

This system allows the position of the comb to be adjusted from the cab to control the aggressiveness of the shredder according to the type of product. Allows a uniform flow of the product to the turbine, it prevents the product from overflowing and allows the driver to know if the bale is forcing too much at the shredder. Rear position for the passage of difficult materials, it limits the contact of the product with the shredder. Front position for easy material passage and for high steady workin in strawbedding.

Hydraulically controlled and has 9 mooving speeds from 0 to 20 m/min. The speed is set by the control, and the material is fed evenly to the shredder. It can be operated in forward or reverse. Designed with 8 mm marine chains with bolt-on bars, it is guided and driven hydraulically by nuts for better centering and resistance to bale weights.

Hydraulically swivelling 270° chute located in the extension of the turbine and the straw flow to guarantee a spreading distance of 15 m on the right side and 13 m on the left side. Hydraulically adjustable chute cover to modulate the spreading distance from the cab. This system makes it possible to spread straw in a barn in a single pass.

Electric control for an easy driving from the cab, it’s equipped with a joystick giving the possibility to drive the chute and it’s fitted with a screen to simply use the different functions of the machine.